Tooling Systems

-

> Tooling Systems

Tooling Systems – in Brilliant Shape

BÜFA®-Tooling Systems

Do you need a conventional mould construction system or one with additional features? Conductivity, high-gloss surfaces and high component quality are just some of the advantages of using low-styrene BÜFA®-Tooling Systems for your mould making.

Through innovative product developments, our products meet the requirements of reliable mould making. Only materials with the best properties are used by BÜFA to make the highest quality moulds.

The portfolio also includes BÜFA® Resin VE 6699 Tooling Infusion – a high-performance vinyl ester resin for the infusion process.

This modern, closed process enables emission-free, clean and reproducible working while ensuring maximum dimensional accuracy and surface quality.

Even more effective for better tools

The right moulds are required to make components from glass-fibre-reinforced plastics (GRP). In practice, these tools are often made of GRP themselves. Fibre-reinforced plastics are real allrounders in mould construction. Mould making begins with a positive original model with the necessary dimensional stability and surface quality. A positive or negative mould is made from the master – the variable form is a big positive here.

Only materials with the best product properties are used to make the highest quality moulds in the GRP industry. Extreme styrene and temperature resistance, high mechanical resilience, a good degree of gloss over the long term and dimensional stability are important criteria when choosing a reliable mould construction system

BÜFA® Resin VE 6699 Tooling Infusion is a system that has been specially developed for mould making using the infusion process.

Our aim was to develop a revolutionary mould-making system based on the latest findings in polymer chemistry. For even better tools within a shorter time. In an extremely cost-effective process!

We Offer two Systems

Tooling - the Tried-and-Trusted Standard or the Safety of Conductivity

1. BÜFA®-Standard Tooling System

This consists of BÜFA®-VE Tooling Gelcoats and low-styrene, fast curing and virtually shrinkage-free BÜFA®-Tooling Resin. This system makes it possible to manufacture moulds of the highest technological quality in just one day instead of a week.

Depending on the desired process, you can choose between two resin systems:

- BÜFA® Resin VE 7100 Tooling is ideal for mould making using the hand lay-up or fibre spraying process

- BÜFA® Resin VE 6699 Tooling Infusion is designed for mould making using the closed infusion process

This means that suitable processing options are available for every application.

2. BÜFA®-Conductive Tooling System

The innovative BÜFA® Conductive Tooling System consists of coordinated individual components, various conductive tooling gelcoats, a 1. layer resin and the two mould-making resins.

Here too, both resin variants, BÜFA® Resin VE 7100 Tooling and BÜFA® Resin VE 6699 Tooling Infusion, can be used.

This means that the system can be used in open hand lamination or injection moulding processes as well as in infusion processes, depending on the desired process and mould size.

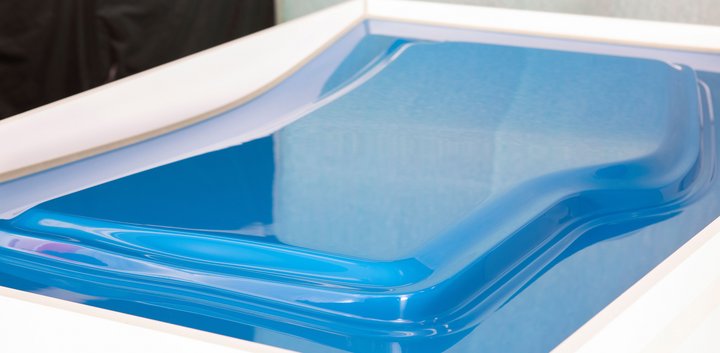

At the heart of the mould-making system is an electrically conductive gelcoat that minimises dust adhesion, drastically reduces demoulding problems and at the same time protects people and materials from electric shocks.

Further advantages include more attractive, high-gloss surfaces, less cleaning effort, faster cycle times, less waste, longer tool life and, on top of that, new degrees of freedom in mould production.

Our Solution

High-tech times three! Thanks to nanotechnology and curing agents that are constantly improving.

- Conductive surface

- Better surface quality

- Moulds with extremely high dimensional stability

The new BÜFA Tooling System is always the right choice when it comes to value for money. It helps you to save time, use less material and even do your part for the environment. All while staying on top of your game in terms of product quality. Mechanical characteristics: Top. Surfaces: brilliant! And the antistatic properties of the mould also help to enhance occupational safety. BÜFA®-Resin VE 6699 Tooling Infusion also provides a high-performance option for the infusion process – for modern, sustainable and reliable mould making.

At a Glance

- Increased process reliability

- Reliably prevents electrostatic build-up and discharge

- Minimised dust adhesion

- Significantly reduced cycle times

- High-quality component surfaces with significantly reduced ripple effect

- Significantly better value for money

In order to provide the maximum contrast with the finished product, black is the best colour for white products. Green is the best colour for white products with dark blue stripes.